Basic Fluid Mechanics: A Liquid

Usually Seeks a Lower Level

By

Charles C. Roberts, Jr., Ph.D., P.E.

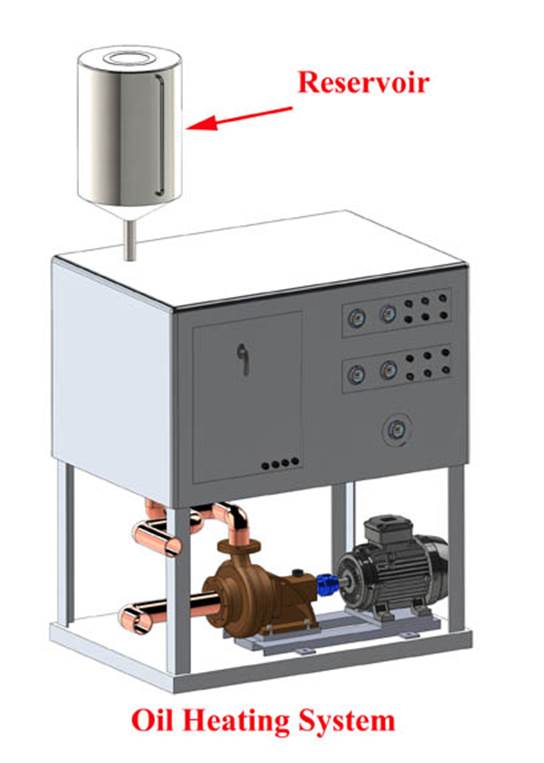

Liquids are utilized in many industrial processes: as a heat transfer medium, a force amplification means (hydraulics), a fuel, etc. Typical designs of such equipment involve a reservoir containing extra liquid involved in the process. The reservoir is often placed above the piece of equipment since fluid pressure due to height is supplied to the system without the need for a pump. Also, entrained air or other gases in the system can rise and be captured in the reservoir. Figure 1 is a drawing of an oil heating system used to deliver heat transfer oil at a particular temperature in an industrial process.† The manufacturer requires the reservoir to be placed above the equipment to assure that oil is always available, air is expelled from the system and that expansion of the oil at various temperatures can be accommodated.

Figure 1

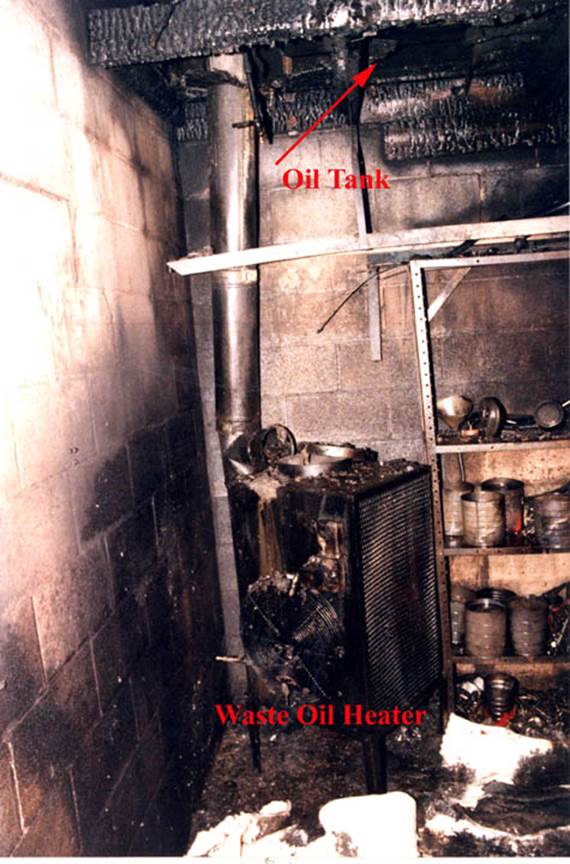

Figure 2

Figure 2 is a view of an oil heat transfer unit involved in a fire that nearly destroyed a small manufacturing facility. The heating system delivered oil at a specific temperature to the molding operation at the facility. During the operating shift at the plant, the temperature controller in the heating system failed, causing the oil temperature to increase, the oil to expand and completely fill the oil reservoir. Workers were horrified to observe oil flowing out of the expansion tank onto the heater, which was immediately ignited by either hot surfaces or electrical equipment. The fire burned rapidly, encompassing the small facility before the fire department arrived.††

Figure 3

Figure 3 shows a waste oil burner/heater in an automotive repair shop. While in operation, a fire developed on top of the heater, causing severe damage to the facility. The waste oil used to fuel the heater was placed higher than the heater, as required by the manufacturer, who designed the system to utilize gravity feed to the oil burner.† The installer placed the waste oil tank just above the heater. Over time, the fuel line fitting loosened and leaked waste oil onto the heaterís upper surface, causing a fire that nearly destroyed the facility.

These two case studies illustrate that liquids seek a lower level and can cause severe damage to property and possible personal injury. When designing or constructing similar systems, the following concepts should be considered:

1. Avoid placing the liquid reservoirs above sensitive equipment. Although these case studies showed how fires developed from combustible liquid leakage from above, other noncombustible liquids can cause severe damage. For instance, leakage of brine from an expansion tank onto electrical equipment can cause severe damage.

2. Install a high liquid level alarm on the liquid reservoir to warn of impending overflow.

3. Provide an adequate overflow drain to another tank or containment area with sufficient capacity to handle the overflow.

Whenever designing systems similar to that which are the subject of this article, keep in mind a basic tenant of fluid mechanics: liquids often seek the lowest level.

Published in Machine Design 2014

†