INTRODUCTION

Variable thermal conductance is achieved in a heat pipe

by controlling liquid or vapor flow. Figure 1 is a review

of the various concepts proposed to vary thermal conductance

in heat pipes. Figure lA shows the concept of tilt control(l).

By tilting the heat pipe in a l-G environment, liquid will

move from one end to the other. As shown in Figure lA, heat

enters the evaporator, -vaporizes liquid and vapor is driven

to the condenser. Normal heat pipe action commences. How-

ever, if the heat pipe is tilted in the other direction,

liquid flows to the condenser and if there is not sufficient

capillary action to bring the liquid back to the evaporator,

heat pipe action stops. Tilting angles between the on and

off angles result in a modulation of thermal conductance.

Figure lB shows the condenser blockage technique. A noncondensible

gas is placed in the heat pipe and during heat

pipe operation this gas is driven to the condenser. Variable

conductance is achieved when this gas front expands or con-

tracts, utilizing either heat or bellows, to block the con-

denser. Evaporating vapor will not penetrate the gas front

and therefore, heat rejection area is limited and thermal

conductance decreases.

Figure lC shows the vapor flow control device using a

valve. This heat pipe is configured for holding evaporator

temperature at a constant value. As the heat in the

evaporator increases, the bimetallic spring opens the

valve and vapor flows through the valve to the condenser.

As the evaporator cools, the bimetallic spring changes

the valve setting and modulates the vapor to hold the

constant temperature.

Another liquid flow control device utilizing an active

pumping means is shown in Figure ID. Here liquid is

pumped into the evaporator utilizing a bubble pump. The

bubble pump can move large amounts of liquid and result

in a wide range of thermal conductances. Power requirements

for this device are on the order of 1% of the power

transmitted by the heat pipe.

Figure IE shows a liquid flow control device utilizing

rotation. With the heat pipe in the position as shown,

liquid is trapped in a U-tube. If the device is rotated

900 so that the U is not visible while viewing along the

horizontal plane, liquid flows to the evaporator and heat

pipe operation commences. Heat flow modulation in this

device is achieved by various angles of rotation.

Figure IF is the heat pipe design that is the subject of

this paper. By bending the body of the heat pipe, liquid

is trapped. Variable bends result in various amounts of

liquid available to the evaporator. This paper presents

data, analysis and application concerning this deformable

heat pipe.

DEFORMABLE BODY HEAT PIPE CONCEPT

Figure 2 depicts the concept of the variable conductance

operation of the deformable body heat pipe. Figure 2A

shows the heat pipe in the high rate of heat transfer

operating mode. All liquid is in the evaporator being

evaporated as or in the stage of drain back from the

condenser. Multiple wicks are all wetted inside the

evaporator. Figure 2B shows the modulating mode. By

deforming the body at the location designated, a given

amount of liquid is trapped in a reservoir. The reservoir

is not sufficient to entrap all liquid, so some

liquid does arrive at the evaporator. It should be

noticed that the liquid reservoir now in the evaporator

is lower and that some wicks are exposed and desaturated.

This results in less liquid available in the evaporator

and a more concentrated evaporating area. The result is

more thermal constriction and loss of heat transfer

rate. As we go to Figure 2C we see the deformable body

device in the off position. The deformation is large

enough such that all returning liquid is entrapped and

no liquid is available for the evaporation. This is the

off mode.

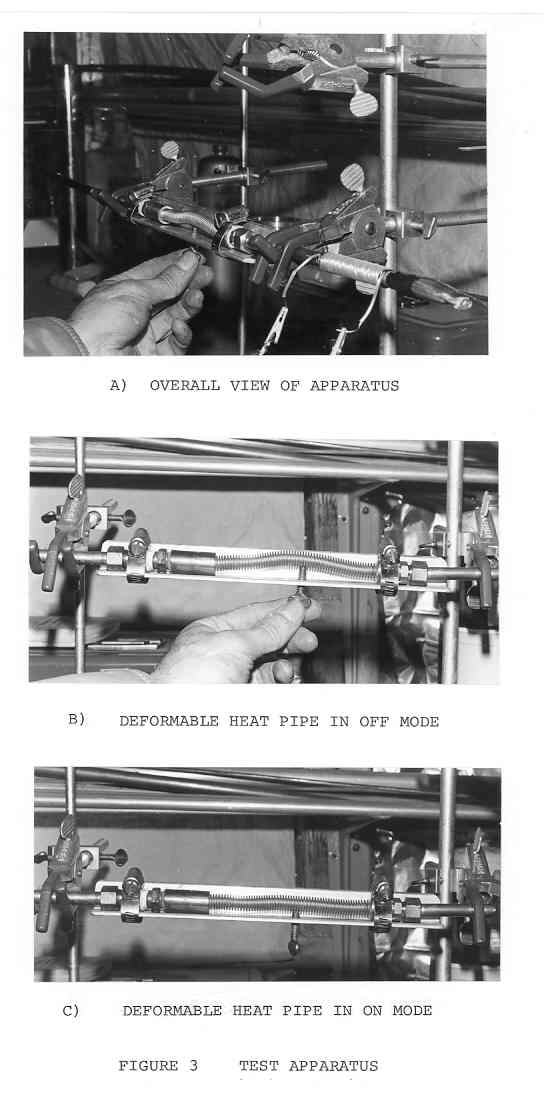

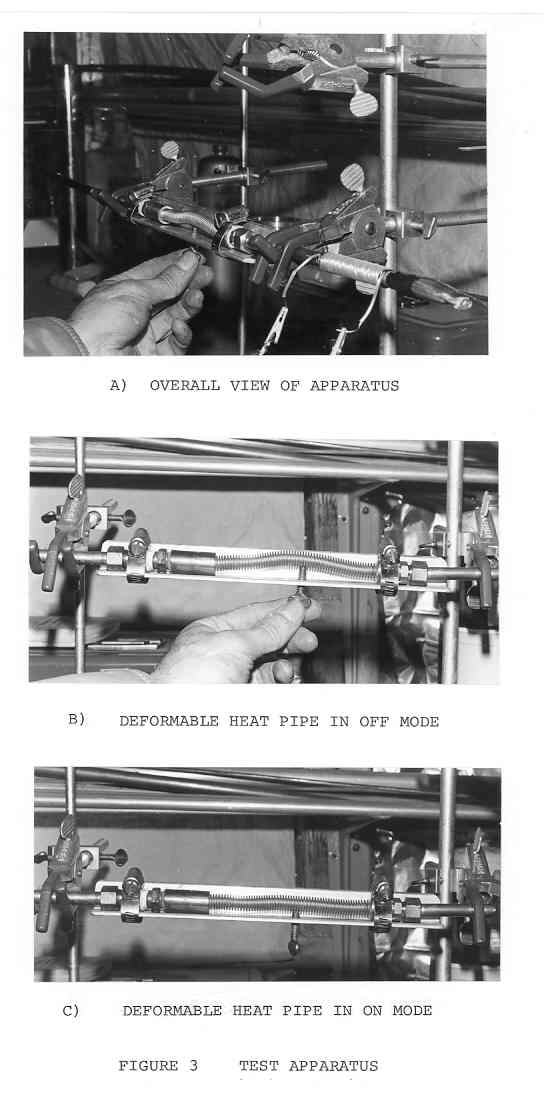

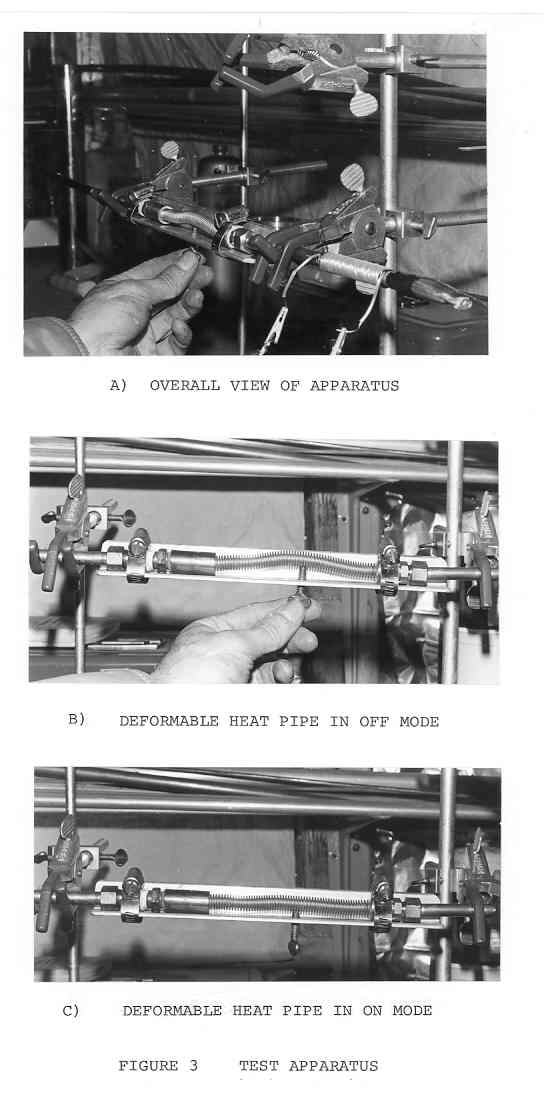

TEST APPARATUS

In order to gage the performance of the deformable body

heat pipe, a test apparatus was constructed. Figure 3

shows the test apparatus in operation. The heat pipe

length was approximately four feet. The tubing diameter

is 3/8 inch in outside diameter. The body material was

copper. The deformable section is made of flexible,

stainless steel tubing. This was coupled to the heat

pipe by typical pipe fittings. Normally, the body material

would be welded into the heat pipe itself. Figure

3A is an overall view of the apparatus. As shown in

Figure 3B the body can be deformed by a thumb screw

moving the deformable portion of the heat pipe up and

down. Various heat transfer rates are obtained by how

much the thumb screw is turned to deform the heat pipe.

Figure 3C shows the heat pipe in the on mode. A small

nichrome wire wrap heater was placed at one end and

thermocouples were mounted in the evaporator to determine

temperature rise in the evaporator and gage the operation

of the device. Methanol was used as the working fluid.

Tests were run at various power levels and various periods

of time. Thermal conductance was altered simply by turning

the thumb screw.

EXPERIMENTAL RESULTS

For a test period of approximately five hours, data was

recorded on evaporator temperatures and heat transfer

rates of the system.

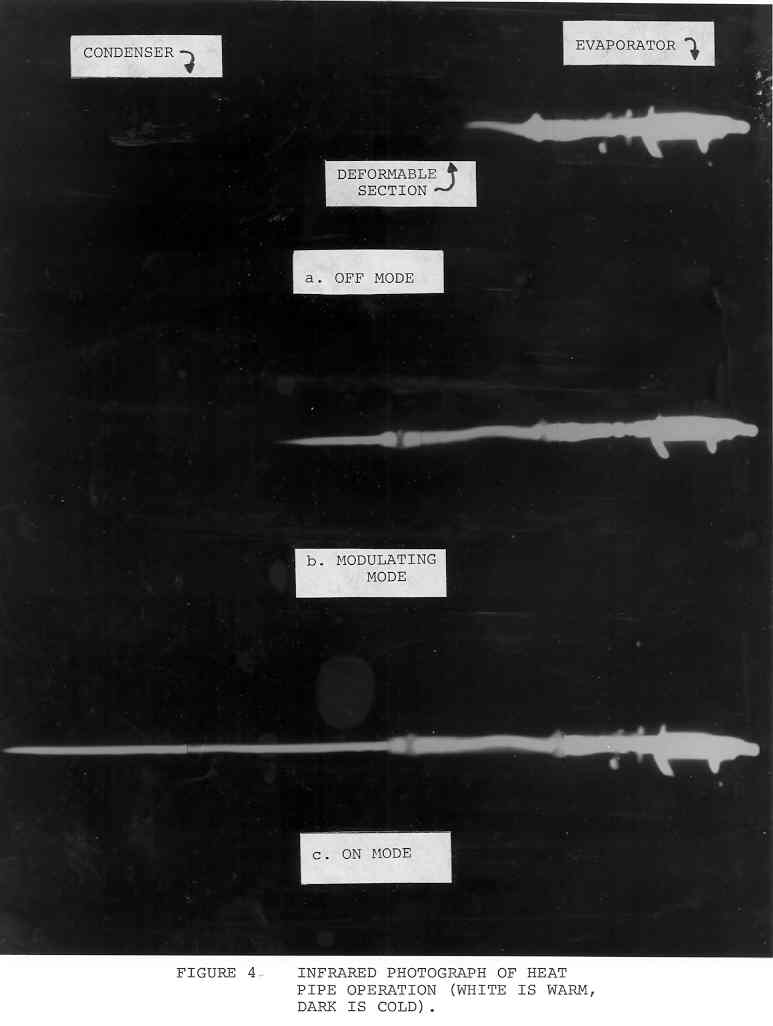

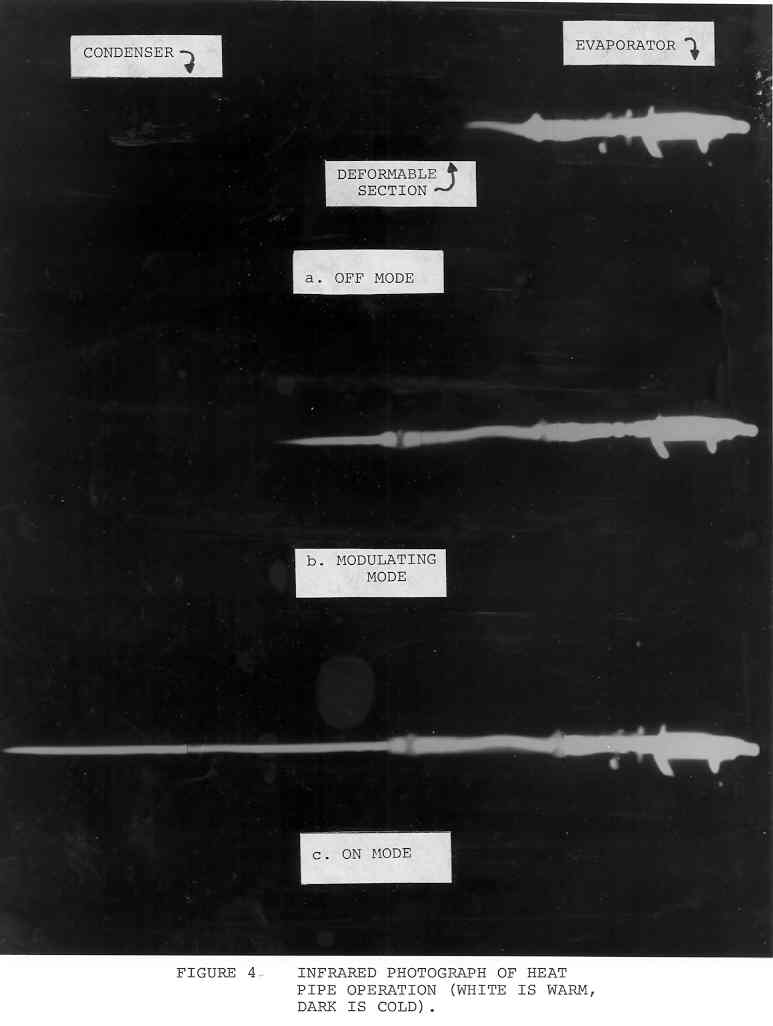

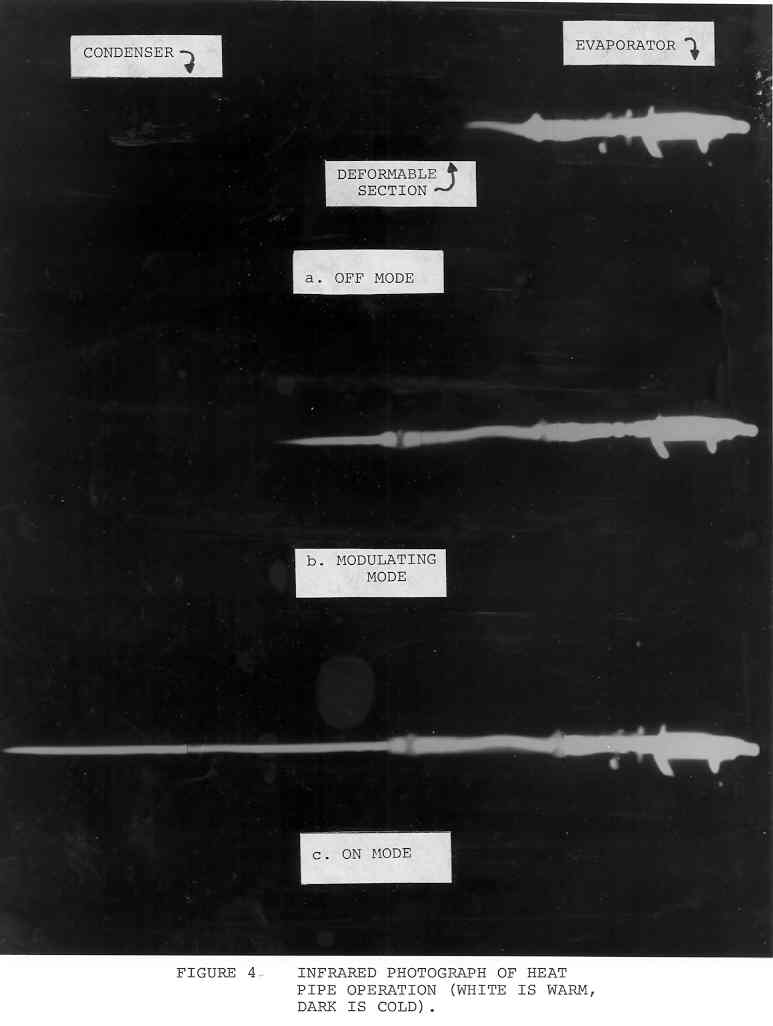

Figure 4 is an infrared photograph of the operation of

the heat pipe. High temperatures are depicted as light

areas. Figure 4A shows the heat pipe in the off mode.

No vapor has penetrated beyond the deformable section.

In Figure 4B the bend in the heat pipe is reduced and a

small amount of liquid is released to the evaporator,

resulting in vapor penetration into the condenser. This

is the modulatory mode. Figure 4C is the full on mode and

all liquid is available to the evaporator.

Shown in Figure 5 are the results of this test. Early in

the test phase the heat pipe was allowed to operate at full

power, which was approximately 15.3 watts. Early into the

test, at approximately 15 minutes, the heat pipe was turned

off quickly and then turned on again. You could see the

thermal spike going up to approximately 80 C. During this

transient the heat pipe was turned on again totally and we

could see the temperature and wattage coming back to approximately

the same level, demonstrating the repeatability of

this device. During the next test the heat pipe was turned

off entirely and the temperature was allowed to rise

until it stabilized, as shown at the zero watt reading.

After five to six minutes of this mode the thumb screw

was backed off to come to an intermediate heat transfer

rate. This turned out to be approximately 7.8 watts.

That temperature was held for a period of time and then

the heat pipe was turned off again. Again the temperature

rose until the zero watt reading was maintained.

The repeatability appeared to be very good, considering

the simplicity of the apparatus.

Throughout the testing and flexing of the heat pipe, the

deformable portion always came back to center. There was

no apparent evidence of plastic deformation or fatigue.

APPLICATIONS

An application of this device in the solar energy area is

depicted in Figure 6. A heat pipe solar collector transfers

heat passively into a solar storage device. Heat is

stored in this device for immediate usage or for storage

for non-solar hours. The deformable body heat pipe is

placed in the storage device and conducts heat to the

using area. The deformable body is controlled by a thermo-

statically actuated plunger. This plunger senses the environmental

conditions inside of the using area and adjusts

the deformable body heat pipe accordingly. The deformable

body heat pipe is sensitive to tilting angles. Therefore,

its best utilization is in a stationary environment, such

as this solar heating system. Once installed, the plunger

can be easily calibrated to the proper temperature by simply

adjusting the plunger with respect to the bimetallic strip.

As the air temperature inside the home increases, the bimetallic

strip changes position, pointing to the 22C position.

This results in a shut off of a significant amount

of heat going to the house because the deformable body heat

pipe is trapping liquid in the trap reservoir. As the

temperature inside goes down, more liquid is released to

the heat pipe and heat transfer increases. This is a simple

feed back mechanism that requires no energy to operate.

It is interesting that coupling a heat pipe solar

collector and the deformable body heat pipe can achieve

a very nearly passive system. No external energy is

required for operating control systems.

CONCLUSIONS

The performance of the deformable body variable conductance

heat pipe has been demonstrated through a simple

experimental apparatus. The device has potential in

stationary systems, where passive variable conductance

over wide temperature ranges are required. Coupling this

device to a storage unit that is supplied by a heat pipe

solar collector, one can achieve a very nearly passive

solar heating system. Data shows the heat pipe to vary

thermal conductance over a wide range of wattage with

relatively little leakage in the off mode.

REFERENCES

1. Q-Dot Corporation, 151 Regal Row, Suite

120, Dallas, Texas

.

2. Heat Pipe Design Handbook, DRDN. SE-345T.

3. Roberts, Charles C., "A Variable Conductance

Heat Pipe Using Bubble Pump Injection", 2nd

International Heat Pipe Conference, Bologna,

Italy.

BACK TO C. ROBERTS CONSULTING ENGINEERS HOME PAGE,

WWW.CROBERTS.COM

DEFORMABLE BODY HEAT PIPE CONCEPT

Figure 2 depicts the concept of the variable conductance operation of the deformable body heat pipe. Figure 2A shows the heat pipe in the high rate of heat transfer operating mode. All liquid is in the evaporator being evaporated as or in the stage of drain back from the condenser. Multiple wicks are all wetted inside the evaporator. Figure 2B shows the modulating mode. By deforming the body at the location designated, a given amount of liquid is trapped in a reservoir. The reservoir is not sufficient to entrap all liquid, so some liquid does arrive at the evaporator. It should be noticed that the liquid reservoir now in the evaporator is lower and that some wicks are exposed and desaturated. This results in less liquid available in the evaporator and a more concentrated evaporating area. The result is more thermal constriction and loss of heat transfer rate. As we go to Figure 2C we see the deformable body device in the off position. The deformation is large enough such that all returning liquid is entrapped and no liquid is available for the evaporation. This is the off mode.

TEST APPARATUS

In order to gage the performance of the deformable body heat pipe, a test apparatus was constructed. Figure 3 shows the test apparatus in operation. The heat pipe length was approximately four feet. The tubing diameter

is 3/8 inch in outside diameter. The body material was

copper. The deformable section is made of flexible,

stainless steel tubing. This was coupled to the heat

pipe by typical pipe fittings. Normally, the body material

would be welded into the heat pipe itself. Figure

3A is an overall view of the apparatus. As shown in

Figure 3B the body can be deformed by a thumb screw

moving the deformable portion of the heat pipe up and

down. Various heat transfer rates are obtained by how

much the thumb screw is turned to deform the heat pipe.

Figure 3C shows the heat pipe in the on mode. A small

nichrome wire wrap heater was placed at one end and

thermocouples were mounted in the evaporator to determine

temperature rise in the evaporator and gage the operation

of the device. Methanol was used as the working fluid.

Tests were run at various power levels and various periods

of time. Thermal conductance was altered simply by turning

the thumb screw.

EXPERIMENTAL RESULTS

For a test period of approximately five hours, data was

recorded on evaporator temperatures and heat transfer

rates of the system.

Figure 4 is an infrared photograph of the operation of

the heat pipe. High temperatures are depicted as light

areas. Figure 4A shows the heat pipe in the off mode.

No vapor has penetrated beyond the deformable section.

In Figure 4B the bend in the heat pipe is reduced and a

small amount of liquid is released to the evaporator,

resulting in vapor penetration into the condenser. This

is the modulatory mode. Figure 4C is the full on mode and

all liquid is available to the evaporator.

Shown in Figure 5 are the results of this test. Early in

the test phase the heat pipe was allowed to operate at full

power, which was approximately 15.3 watts. Early into the

test, at approximately 15 minutes, the heat pipe was turned

off quickly and then turned on again. You could see the

thermal spike going up to approximately 80 C. During this

transient the heat pipe was turned on again totally and we

could see the temperature and wattage coming back to approximately

the same level, demonstrating the repeatability of

this device. During the next test the heat pipe was turned

off entirely and the temperature was allowed to rise

until it stabilized, as shown at the zero watt reading.

After five to six minutes of this mode the thumb screw

was backed off to come to an intermediate heat transfer

rate. This turned out to be approximately 7.8 watts.

That temperature was held for a period of time and then

the heat pipe was turned off again. Again the temperature

rose until the zero watt reading was maintained.

The repeatability appeared to be very good, considering

the simplicity of the apparatus.

Throughout the testing and flexing of the heat pipe, the

deformable portion always came back to center. There was

no apparent evidence of plastic deformation or fatigue.

APPLICATIONS

An application of this device in the solar energy area is

depicted in Figure 6. A heat pipe solar collector transfers

heat passively into a solar storage device. Heat is

stored in this device for immediate usage or for storage

for non-solar hours. The deformable body heat pipe is

placed in the storage device and conducts heat to the

using area. The deformable body is controlled by a thermo-

statically actuated plunger. This plunger senses the environmental

conditions inside of the using area and adjusts

the deformable body heat pipe accordingly. The deformable

body heat pipe is sensitive to tilting angles. Therefore,

its best utilization is in a stationary environment, such

as this solar heating system. Once installed, the plunger

can be easily calibrated to the proper temperature by simply

adjusting the plunger with respect to the bimetallic strip.

As the air temperature inside the home increases, the bimetallic

strip changes position, pointing to the 22C position.

This results in a shut off of a significant amount

of heat going to the house because the deformable body heat

pipe is trapping liquid in the trap reservoir. As the

temperature inside goes down, more liquid is released to

the heat pipe and heat transfer increases. This is a simple

feed back mechanism that requires no energy to operate.

It is interesting that coupling a heat pipe solar

collector and the deformable body heat pipe can achieve

a very nearly passive system. No external energy is

required for operating control systems.

CONCLUSIONS

The performance of the deformable body variable conductance

heat pipe has been demonstrated through a simple

experimental apparatus. The device has potential in

stationary systems, where passive variable conductance

over wide temperature ranges are required. Coupling this

device to a storage unit that is supplied by a heat pipe

solar collector, one can achieve a very nearly passive

solar heating system. Data shows the heat pipe to vary

thermal conductance over a wide range of wattage with

relatively little leakage in the off mode.

REFERENCES

1. Q-Dot Corporation, 151 Regal Row, Suite

120, Dallas, Texas

.

2. Heat Pipe Design Handbook, DRDN. SE-345T.

3. Roberts, Charles C., "A Variable Conductance

Heat Pipe Using Bubble Pump Injection", 2nd

International Heat Pipe Conference, Bologna,

Italy.

BACK TO C. ROBERTS CONSULTING ENGINEERS HOME PAGE,

WWW.CROBERTS.COM

Shown in Figure 5 are the results of this test. Early in

the test phase the heat pipe was allowed to operate at full

power, which was approximately 15.3 watts. Early into the

test, at approximately 15 minutes, the heat pipe was turned

off quickly and then turned on again. You could see the

thermal spike going up to approximately 80 C. During this

transient the heat pipe was turned on again totally and we

could see the temperature and wattage coming back to approximately

the same level, demonstrating the repeatability of

this device. During the next test the heat pipe was turned

off entirely and the temperature was allowed to rise

until it stabilized, as shown at the zero watt reading.

After five to six minutes of this mode the thumb screw

was backed off to come to an intermediate heat transfer

rate. This turned out to be approximately 7.8 watts.

That temperature was held for a period of time and then

the heat pipe was turned off again. Again the temperature

rose until the zero watt reading was maintained.

The repeatability appeared to be very good, considering

the simplicity of the apparatus.

Throughout the testing and flexing of the heat pipe, the

deformable portion always came back to center. There was

no apparent evidence of plastic deformation or fatigue.

APPLICATIONS

An application of this device in the solar energy area is

depicted in Figure 6. A heat pipe solar collector transfers

heat passively into a solar storage device. Heat is

stored in this device for immediate usage or for storage

for non-solar hours. The deformable body heat pipe is

placed in the storage device and conducts heat to the

using area. The deformable body is controlled by a thermo-

statically actuated plunger. This plunger senses the environmental

conditions inside of the using area and adjusts

the deformable body heat pipe accordingly. The deformable

body heat pipe is sensitive to tilting angles. Therefore,

its best utilization is in a stationary environment, such

as this solar heating system. Once installed, the plunger

can be easily calibrated to the proper temperature by simply

adjusting the plunger with respect to the bimetallic strip.

As the air temperature inside the home increases, the bimetallic

strip changes position, pointing to the 22C position.

This results in a shut off of a significant amount

of heat going to the house because the deformable body heat

pipe is trapping liquid in the trap reservoir. As the

temperature inside goes down, more liquid is released to

the heat pipe and heat transfer increases. This is a simple

feed back mechanism that requires no energy to operate.

It is interesting that coupling a heat pipe solar

collector and the deformable body heat pipe can achieve

a very nearly passive system. No external energy is

required for operating control systems.

CONCLUSIONS

The performance of the deformable body variable conductance

heat pipe has been demonstrated through a simple

experimental apparatus. The device has potential in

stationary systems, where passive variable conductance

over wide temperature ranges are required. Coupling this

device to a storage unit that is supplied by a heat pipe

solar collector, one can achieve a very nearly passive

solar heating system. Data shows the heat pipe to vary

thermal conductance over a wide range of wattage with

relatively little leakage in the off mode.

REFERENCES

1. Q-Dot Corporation, 151 Regal Row, Suite

120, Dallas, Texas

.

2. Heat Pipe Design Handbook, DRDN. SE-345T.

3. Roberts, Charles C., "A Variable Conductance

Heat Pipe Using Bubble Pump Injection", 2nd

International Heat Pipe Conference, Bologna,

Italy.

BACK TO C. ROBERTS CONSULTING ENGINEERS HOME PAGE,

WWW.CROBERTS.COM

CONCLUSIONS

The performance of the deformable body variable conductance heat pipe has been demonstrated through a simple experimental apparatus. The device has potential in stationary systems, where passive variable conductance over wide temperature ranges are required. Coupling this device to a storage unit that is supplied by a heat pipe solar collector, one can achieve a very nearly passive solar heating system. Data shows the heat pipe to vary thermal conductance over a wide range of wattage with relatively little leakage in the off mode.

REFERENCES

1. Q-Dot Corporation, 151 Regal Row, Suite 120, Dallas, Texas

. 2. Heat Pipe Design Handbook, DRDN. SE-345T.

3. Roberts, Charles C., "A Variable Conductance Heat Pipe Using Bubble Pump Injection", 2nd International Heat Pipe Conference, Bologna, Italy.

BACK TO C. ROBERTS CONSULTING ENGINEERS HOME PAGE,

WWW.CROBERTS.COM

WWW.CROBERTS.COM